Back to Basics Series – Day 5

29th March

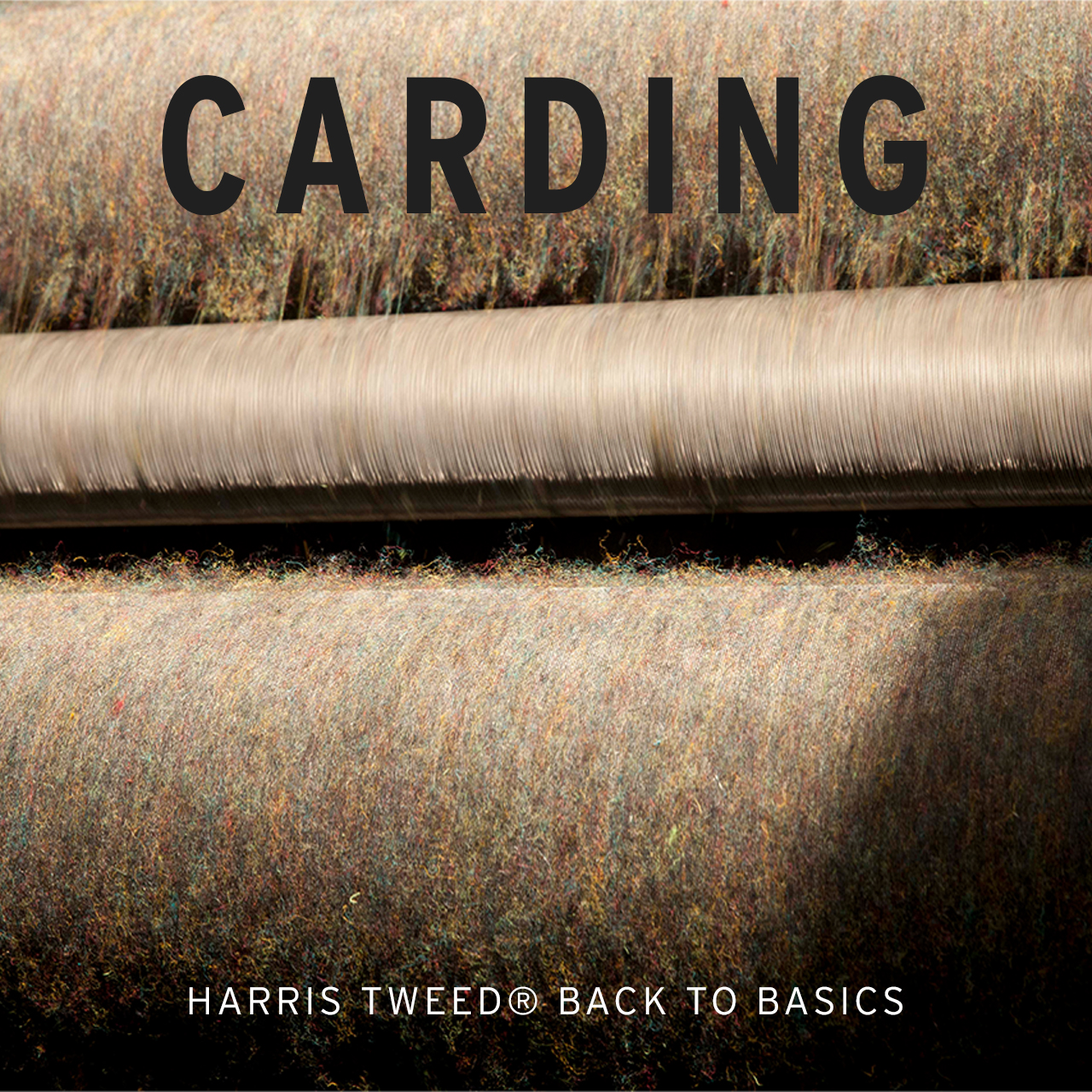

Carding

The blended wool mixture needs to be carded to the correct “weight”. The wool mixture passes through a series of finely spiked rollers, which thoroughly blend the colours together, and ensure the individual wool fibres are running parallel to each other. This process converts the loose dyed wool mixture into a continuous matted web of fibres, which is then divided into individual ribbons of fine roved wool. These delicate ribbons of roved wool are wound gently onto spools, ready to be loaded onto the spinning frames.